Why Validation Matters

Aerodynamic development in motorsport relies on the systematic correlation of multiple data sources to make confident decisions. While computational tools have advanced significantly, the complex nature of racing aerodynamics with high lift devices, turbulent flows, and multidisciplinary vehicle interactions creates inherent uncertainties that must be understood and managed through rigorous experimental validation.

When Data Sources Disagree

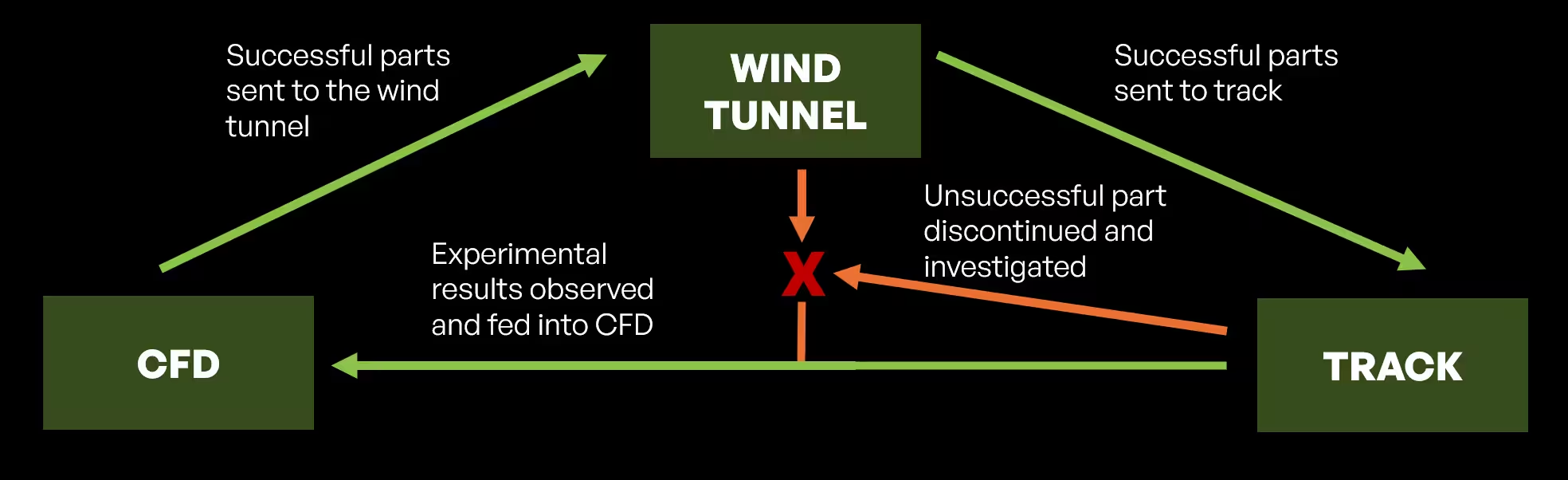

CFD remains an invaluable development tool, providing rapid iteration capabilities and detailed flow field insights. However, it must be coupled with experimental testing and correlation work due to inherent limitations in computational approaches. The RANS framework offers various turbulence models such as k-ω which attempts to improve fidelity in near walls and in adverse pressure gradients. More sophisticated approaches like DES (Detached Eddy Simulations) and LES provide better resolution of unsteady phenomena but at significantly higher computational cost. But however sophisticated the model is, it ends up being a model, an attempt to imitate reality, and without understanding what is happening in the tunnel and in track, the model cannot be optimised to give accurate results.

This drives teams toward wind tunnel and track testing, but these experimental approaches introduce their own complexities. Systematic errors arise from tunnel walls, model support stings, imperfect boundary layer formations on the road, near-wall interactions and blockage ratios—making once again an imperfect test that must be evaluated against the track data.

On the trackside, aerodynamic surface quality presents additional challenges. Surfaces may not achieve the same polish as wind tunnel models or CFD simulations, and preparation quality can vary from mechanic to mechanic. Without repeatable aerodynamic surfaces, testing, data collection, and performance evaluation can show significant variations. Establishing standardised procedures becomes crucial. These procedures teach mechanics to execute each task step by step in a consistent manner, eliminating guesswork and ensuring that aerodynamic surfaces maintain consistent quality across all testing and competition scenarios.

Understanding where gaps exist between CFD, wind tunnel, and trackside data, and why they occur, becomes crucial for leveraging each tool's strengths. Systematic gap analysis allows teams to identify trends in CFD that provide reliable expectations whilst accounting for the inherent uncertainty in experimental results. This understanding transforms how teams interpret their data, moving from reliance on any single source to intelligent correlation across multiple validation methods.